Are you still one of those people who go to shops and department stores to buy food, clothes, and electrical appliances, etc.? Or are you a user of the modern, virtual shopping malls that are open at any time of the day or night and whose range of goods far surpasses that of physical shops? Whichever group you belong to: just read on.

Online trading and shipping

Online trading is growing every year. Unlike in local shops, however, the customer cannot simply take the goods home after giving them a thorough inspection; instead, they must be brought to the customer. For large products, such as refrigerators, this is done by a forwarding agent, for smaller articles, in a parcel, and for small, flexible products, such as textiles, in an opaque plastic or paper envelope which is sealed with an adhesive.

Temperature-resistant adhesive for padded envelopes

This envelope has several functions at once, e.g.

- It must be opaque so that no one can see which product is contained within.

- It must protect the product against environmental influences.

- It must be closed in such a way that nobody can take or add anything unnoticed.

And this at any time of day or night and in summer as well as in winter!

These requirements also place high demands on the adhesive, which is responsible for the secure closure of the envelope.

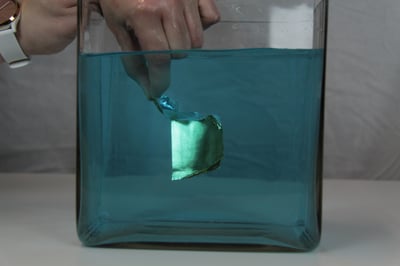

On the one hand, the adhesive, which is simply coated onto the closure flap of the envelope as a narrow strip a few millimeters wide, must have a high initial adhesion. This is because the envelope is filled, sealed, labelled and shipped immediately. There is no time to press the closure tab of the envelope firmly and wait until the adhesive finally sticks. Afterwards, the envelope will go on journeys all over the world. In tropical regions with high temperatures and high humidity or in areas as cold as the Arctic. And the adhesive must always keep the envelope neatly sealed.

This requirement can only be met with carefully selected and tested adhesive formulations. An incorrectly selected adhesive will see the padded envelope open during transport. The goods will fall out and get damaged or get lost. Complaints are inevitable.

Although it is only a matter of sending goods or simple documents, the requirements placed on the envelope are already very high.

Adhesive applications for shipping in the security sector

Applications in the security sector have even higher requirements. Here we are talking about the dispatch of cash, highly valuable documents or forensic samples. You can read about the requirements placed on an envelope in this sector and the special solutions that exist in our blog “What is important when transporting money and valuable items?”

Summary

I'll sum it up:

- Padded envelopes made of plastic must fulfill several functions.

- The adhesive must ensure the secure closure of the envelope.

- It must do so in regions with extremely hot or cold conditions.

- Applications in security areas require special solutions.

Talk to our adhesive experts to find the right adhesive for your application. We look forward to hearing from you and are at your disposal.

![Anwendungsbeispiel-L1-1452[1]-1](https://blog.artimelt.com/hs-fs/hubfs/Anwendungsbeispiel-L1-1452%5B1%5D-1.jpg?width=400&name=Anwendungsbeispiel-L1-1452%5B1%5D-1.jpg)